The Morris Com Loop Antenna

An Internally Mounted, Vertically Polarized,

Full Wave Loop Comm Antenna

for homebuilt composite aircraft

by David L. Morris, N5UP

The author has several years of experience building loopantennas in fixed locations. While the theory of loop

antennas is well understood, the specific application of

this design has not been proven in aircraft. Builders

should not rely on this antenna as their sole method of

communicating until they have proven its operation in their

own aircraft under the range of flight conditions

anticipated.

Revised 18Sep2005 to include new antenna kit and change of name

Synopsis |

Several unique antenna designs have been proposed over the years for composite aircraft. Their lack of metal skin allows antennas to be mounted internally and to radiate virtually without impediment through the fiberglass body. Some Long-Eze's have antennas built into their winglets. The traditional vertical whip antennas with a screen or radial wire ground plane is popular, and a horizontal V- shaped dipole can also be conveniently embedded into the fuselage floor. This article will discuss the design of an antenna that is extremely simple to build and theoretically has improved transmission and reception characteristics versus dipoles, ground plane verticals, and almost all alternative antennas that might be installed. The antenna described here is also vertically polarized, fits inside the tail cone of a fiberglass aircraft, has a low angle of radiation, and does not require a ground plane. Total parts cost can be less than $10 if you have experience building antennas and have all necessary tools. The antenna is technically known as a "vertically polarized, full-wavelength, single loop". Its characteristics have been well known and enjoyed in the ham radio community for years. The unique construction of the Dragonfly and Quickie (including Q-2 and Q-200) now permits this antenna to be put to good use in the tail cone of these aircraft and any others with a 31 inch diameter fiberglass fuselage. It should not be used inside a tailcone made of carbon fiber, because that is a conductive material. Following the example of many previous antenna designers (Beverage, Marconi, Yagi, Zepp, etc.) the author has given this antenna his family name. The term "Com" in the middle of the name can stand for "communications" or for "composite". |

Why Another Antenna? |

Quarter-wave ground-plane verticals are some of the least powerful for communication. And yet that is exactly the type of antenna called for in the Dragonfly plans and used by many builders. It seems there just haven't been any other choices. Most high-gain verticals (5/8 wavelength, J-pole, yagis and collinears) are out of the question, because the longest vertical stretch in a Dragonfly is the 43 inch tail fin, and it contains a pair of carbon fiber spars that would interfere with the nearby antenna. While building the tail cone, it occurred to the author that a full wavelength loop antenna would fit perfectly inside a Dragonfly, Q-2, or other aircraft having a non-metallic tail cone of approximately 31 inches diameter, and that such an antenna could provide all the advantages for which loop antennas are well known. A few of these are discussed below. |

Advantage: Gain |

A full wavelength loop antenna has a small amount of gain (on the order of a dB or two) over a dipole or quarter- wavelength whip antenna. It has an even larger amount of gain over any antenna that is shorter than a quarter wavelength, such as externally mounted fin type antennas, rubber duckies, and helically wound antennas. Among the various shapes available for full-wave loops, the circular form factor produces more gain than square, triangle or delta, and rectangular loops. If you have ever driven past a ham operator's house and marveled at a huge "box kite" sitting on top of a tower, you were probably looking at a "cubical quad" antenna. (The most visible parts of a quad antenna are the bamboo or fiberglass diagonal supports, called "spreaders", but the wire being supported by these spreaders is the active part of the antenna that we are going to build here. We don't need spreaders, because we will attach this wire to the inside of the fuselage tail cone.) The loop antenna is one of the most powerful antennas available for the amount of space it occupies, and has many advantages over other antennas, as we will describe below. To build a "Morris Com Loop", we essentially take one of the square elements of a quad antenna, round it into a loop, and install it inside a composite tailcone. |

Advantage: Angle of Radiation |

In free space, the radiation from this antenna is predominantly concentrated at low angles of radiation, similar to the pattern of a vertical whip. Thus, this antenna is effective for aircraft use where ground stations must be contacted at angles below the horizontal. One other omnidirectional gain antenna considered by the author, the 5/8 wavelength vertical, has a higher angle of radiation and is thus not optimal for aircraft use. |

Advantage: Lobes |

A single loop concentrates a larger portion of its radiation perpendicular to the plane of the loop (toward the front and rear of the aircraft), but the side lobes are strong enough that no noticeable degradation of signal strength should occur, even if the ground station is off the wing tips of the aircraft. (This is a presumption based on antenna theory and subjective tests carried out by the author by rotating a test antenna while listening to transmissions by aircraft. Some variance from the theoretical predictions can be expected due to the influence of metal parts in the aircraft.) |

Advantage: Engine Noise |

Closed loop antennas such as the one presented here are theoretically more immune to static such as that generated by the aircraft engine, strobe lights, and other sources of noise, when compared with whip verticals. However, no definitive tests have been performed yet to see if there is that difference in noise immunity produces a quieter signal in real-life operation. |

Construction |

The antenna can be made of any copper wire, copper tape, tubing, or other metal material. In theory, larger diameters (such as 14 gauge wire) provide a better signal on the edges of the aircraft band, but in practice, this is probably negligible, and you might as well save weight and use the same 20 or 22 gauge Tefzel wire you are using for the rest of your wiring. The wire loop is installed inside the aircraft around the tail cone at the point where the tail cone is approximately 30.75 inches in diameter. On a typical Dragonfly, this point will be found a short distance behind the wing drag bulkhead (see Figure 1). Use dabs of epoxy, Bondo, or any other suitable non-conductive material to attach the wire to the inside wall of the fuselage. Since epoxy is a non-conductor, it is not necessary for the wire to be raised or insulated from the surface, so use your own creativity here. The circumference of a circle is c = pi * d where d is the diameter, and pi is 3.14159. We design the antenna to resonate near the center of the aircraft band, at about 125 MHz, requiring a total wire length of 96.5 inches (see Formulas Used below). This produces a loop with an approximate diameter of 30.75 inches. Since the interior of the tail cone is slightly distorted from a perfect circle, the exact location must be derived by trial-fitting. If you use non-insulated wire, this dimension should be fairly accurate. If you use insulated wire, the insulation can change the resonant frequency and cause slight deviations from the theoretical wire lengths, so you will need to "tune" the antenna after construction (see details below). Try to keep the wire as far as possible away from any metal parts, such as the wing fittings, bellcranks, control rods, and such like. If you have to, bend the loop into a bit of an odd shape rather than allowing it to get too close to these metal parts. NOTE: If you have already installed a ground plane in the fuselage floor and the loop wire will have to run across the top of the ground plane, it will interfere with the Morris Com Loop. If you cannot remove the ground plane because it has been glassed in, I do not recommend trying the loop antenna! Likewise, attaching the loop to the aft face of the seatback bulkhead is not recommended, because there will be people sitting there, and that will interfere with the radio signals as well as producing an unhealthy RF energy field going straight into their backs. |

|

Install the antenna wire so the two ends wind up forming a

small gap at the 3 o-clock or the 9 o-clock point in the

wire loop, as shown in Figure 2. (It doesn't matter whether

you choose the left or right side, so make it convenient on

yourself.) This gap is called the Feed Point, and it is

where the coax will be connected. You may wish to leave the

ends about a half inch longer than the calculations specify,

in order to have some leeway later on when tuning the

antenna. Placing the gap halfway up the fuselage side

causes the antenna to radiate in vertical polarization. (If

you deviate from the plans and place the gap at the top or

bottom, the antenna will become horizontally polarized, and

you will suffer a significant decrease in signal strength

both on transmit and receive, so don't do it!)

If you are a perfectionist, don't forget that the Dragonfly or Q-2 sits nose-high when parked, and that the plane of the antenna loop should be vertical in flight. If you are not a perfectionist, don't worry too much about being 10 or 20 degrees off, because you won't hear the difference in signal strength anyway. In short, the antenna can be installed at a bit of a slant if necessary to clear obstacles inside the fuselage. |

|

Feeding the Antenna |

A single full-wavelength loop exhibits an impedance of about

100 Ohms. In order to match this to standard RG-58, RG-400, or RG-142

coax (53 Ohms), a quarter-wavelength matching section is

fashioned from a 15.5 inch length of 75 Ohm RG-179, RG-302, or RG-59 coax

(readily available at Radio Shack and other electronic parts

retailers or buy my kit below).

Attach one end of this coax matching section to the Feed Point described above.

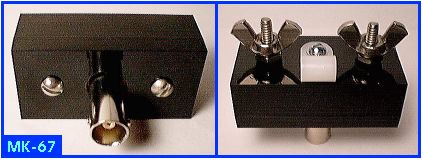

Buying Tip: In the past, I recommended soldering the coax to the ends of the antenna loop wire.

But now there is finally a nice alternative for the feed point. Buy a MK-67 center insulator

from ElectronicsUSA.com or included in my kit below. It was designed for a dipole antenna but works perfectly here.

Attach it to the fuselage wall using the

nylon cable tie you see between the wing nuts (be creative!). Then wrap each end of the antenna loop wire under its own wing nut

or for a more professional installation, crimp a ring terminal onto each end of the antenna loop wire and then use those on the wing nuts.

Finally, plug the quarter wave coax matching section into the BNC connector on the insulator.

(See Figure 2.) There is no up or down on the connector, so you can attach either end of the loop wire to either one of the wing nuts. If you decide to solder the coax to the loop and not use the pre-fab center connector, use only rosin core solder and then attach the coax to the fuselage wall using a suitable strain relief (Adel clamps, etc.) so the solder connection is not under stress. |

|

Placement of the coax is non-critical, but at least the first foot or so should leave the antenna perpendicular to the wire if at all possible. In other words, try to position the coax so it leaves the vicinity of the antenna wire as quickly as possible. The rest of the coax may then be coiled, wrapped, snaked or otherwise positioned as required inside the aircraft interior. At the other end of the 15.5 inch section of coax, attach your RG-400 or RG-142 coax (of any length) that runs forward to the radio, using BNC connectors. Resist the temptation to install any baluns, loading coils, or other devices you might have left over from a previous antenna. The quarter-wave matching section is all you need, and adding anything else will interfere with its operation. |

|

Tuning the Antenna |

All antenna calculations are estimates and are based on an antenna floating in free space. The theoretical computations cannot possibly account for the impact that other objects will have in the vicinity of the antenna, for example your wing lift and drag fittings, carbon fiber in the spar, control cables, bellcranks, rods, and so on. So, some minor tuning of every antenna is generally required. Buy an SWR bridge that is designed for VHF, or borrow one from a ham who has 2 Meter radios or from an avionics technician. Check your SWR at center of the frequency range most likely to be encountered. If it is less than 1.5 to 1, try the outer ends of the aircraft band. If it less than 1.5:1 everywhere, consider yourself lucky and skip the rest of this discussion on tuning! If it is over 1.5:1 anywhere, then you might want to do a little work on the antenna to tune it to the right length. If it is over 2:1 then you definitely need to do the following: Tune your transmitter to a frequency about 2 MHz lower than the center frequency and see if the SWR gets better or worse. If it gets better, the antenna is too long. If it gets worse, the antenna is too short. To verify this, tune the opposite direction, that is, 2 MHz above the design frequency and check the SWR again. It should show the opposite results. You can add or remove wire from either end of the antenna loop. It doesn't matter. If you happen to spot the exact frequency where your SWR dips to its lowest point, you're in luck: just add or subtract 1/2 inch of wire for every Megahertz of offset you need to center it on the desired design frequency. Add wire to bring the center frequency down, and subtract wire to bring the frequency up. (Note: Don't spend a whole lot of time trying to get a perfect 1:1 SWR. If you are below 2:1 across the entire aircraft band, you will be fine. The difference in line loss going from 1.5:1 to 2:1 is only about 0.2 dB and will not be noticeable. The author has spent years talking to people on opposite sides of the earth with a 2:1 SWR on some of his experimental antennas!) Once you have finalized the loop wire length, you can slip some shrink tubing onto the loop wire and solder the coax in place at its final location. Slide the shrink tubing over the job and heat it to create a nice, clean installation. Then go flying! |

A Note on Coax Selection |

VHF purists will tell you RG-8 coax is highly recommended despite its higher weight and more rigid structure, because it has about 1/2 the transmission line loss of the thinner and lighter RG-58 coax. (This means if your transmitter output is 10 Watts and you send it through 100ft of RG-8 coax, you only get 5 Watts to the antenna, but RG-58 only allows 2.5 Watts to be delivered to the antenna!) But none of us are building 100 foot long aircraft, RG-8 is heavy and difficult to bend around in tight instrument panel interiors, and the insulation used in RG-8 and RG-58 is no longer allowed in certified aircraft. So, your best choices are the latest and greatest RG-400 or RG-142. Of these, RG-400 is the better choice because of double braid and stranded center conductor. But either one will work fine. Just try to keep your coax reasonably short and don't use that unmarked stuff you found in a junkyard or cut off your last TV antenna when you switched to cable! Coaxial cable does deteriorate over time in the weather, and using new coax might make the difference between getting clearance into the Class B airspace or having to wait for someone to finally hear your weakened signal! Buying tip: AeroElectric Connection sells RG-400 coax with connectors installed for a reasonable price, if you are not handy installing BNC connectors. |

RF Exposure |

With a 10 Watt transmitter, at 3 feet from the antenna center (roughly where the pilot sits), the estimated power density is 0.2232 mw/cm^2. In the aircraft band, the maximum permissible exposure (MPE) in controlled environments is 1.00 mw/cm^2. The MPE in uncontrolled environments is 0.20 mw/cm^2. According to my computations, this antenna would meet the controlled MPE limit if installed at least 1.47 feet away from the pilot, and the uncontrolled MPE limit would be met at 3.22 feet away from the pilot. Since pilots typically make very short transmissions with an extremely low "duty cycle", this antenna is perfectly safe when installed behind the wing, according to the FCC RF exposure regs. For more information on the FCC's new RF safety regulations, check out the References section below. |

Testing |

It is recommended that you conduct your own tests of the new antenna versus an existing vertical or a borrowed whip antenna. A high quality coaxial A-B switch will make the job easier than switching connectors. Fly to a fringe area, and listen to the signal strength of a ground station (for instance ATIS) with each of the two antennas. Try flying toward the station, away from the station, and with the station off one wing. Switch back and forth and note any differences. You will get the best test results with a distant station that is noisy. Remember that technically the antenna concentrates its firepower through the "barrel" of the loop, and reception may be weaker off the sides. |

Figure 3 - Author's test antenna with quarter-wave coax matching section at the 9 o-clock position |

|

|

The author built a test antenna to experiment with the front- to-side ratio and gain, by nailing two yardsticks into a cross and tacking the wire in place around the circumference. Figure 3 is a photograph of the test antenna with the quarter-wave matching section visible at the 9 o-clock position. If you build and test a "Morris Com Loop" antenna, the author would appreciate hearing your observations and seeing photos of your installation. E-mail him at Dave @ DaveMorris dot com |

|

Buy One Now! |

The author has kits available for sale, containing

You can order directly from this page by clicking on the button below. Please allow 4-6 weeks for Priority Mail shipping in the USA, or slightly longer for overseas air mail shipping.

|

Formulas Used |

(f = design frequency in MHz) |

References |

|

Other Articles by the Author |

Dave Morris has written for QST, Interface Age, and other magazines. He has been a ham operator since 1971 and holds an FCC Amateur Extra Class license. He has been a pilot since 1983 and has found many strange things to write about during that time. Here is a list of some of the articles he has managed to sneak past the editors and somehow get published. |

No part of this article may be reproduced, duplicated, printed, copied, or downloaded except for personal use.